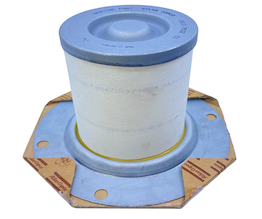

Description

The Atlas Copco Air/Oil Separator 2901008500 is a premium OEM-quality separation element engineered to deliver superior oil removal performance in Atlas Copco rotary screw air compressor systems. This separator is essential for maintaining optimal air purity while minimizing oil carryover, protecting your compressed air system from contamination and ensuring reliable operation across industrial and heavy-duty applications.

Engineered with advanced coalescing microfiber technology featuring high-precision filter media, the 2901008500 separator efficiently captures fine oil aerosols and directs recovered oil back into the compressor’s lubrication circuit. The separator is manufactured with American HV (Binzer) and Lydall fiberglass filter material, ensuring superior filtration performance. This efficient recovery mechanism not only safeguards downstream equipment from oil contamination but also reduces oil consumption and significantly lowers operating costs while maintaining system efficiency.

With a robust, high-temperature resistant construction, this separator delivers consistent, reliable performance throughout extended service intervals with a typical service life of 3,500 to 5,200 operating hours. Featuring filter accuracy of 0.1 micrometers and filtration efficiency of 99.99%, this separator meets the highest standards for compressed air quality. Whether deployed in manufacturing facilities, processing plants, or continuous heavy-duty operations, this air/oil separator maintains compressor efficiency, protects internal components, and guarantees superior compressed air quality for demanding industrial applications.

- Filter accuracy: 0.1 micrometer precision

- Filtration efficiency: 99.99%

- American HV and Lydall fiberglass filter media

- Service life: 3,500-5,200 operating hours

- Advanced coalescing microfiber technology

- Suitable for Atlas Copco oil-injected rotary screw compressors

- Ideal for industrial, manufacturing, and production environments

- Compatible with processing, automotive, and heavy-duty applications

- Used in routine maintenance and comprehensive system overhaul programs

-

Reduces oil consumption and operating costs

-

Protects downstream equipment from contamination damage

-

Ensures clean, reliable, high-quality compressed air output

-

Supports extended compressor life with 3,500-5,200 hour service intervals

-

Meets industry standards for compressed air quality

Reviews

There are no reviews yet.